paper cups

PAPER CUP MANUFACTORING TECHNOLOGY

There is an opinion that glue is used in the production of paper cups. In fact, it is not. Paper cups are made from special laminated paper with low face penetration.

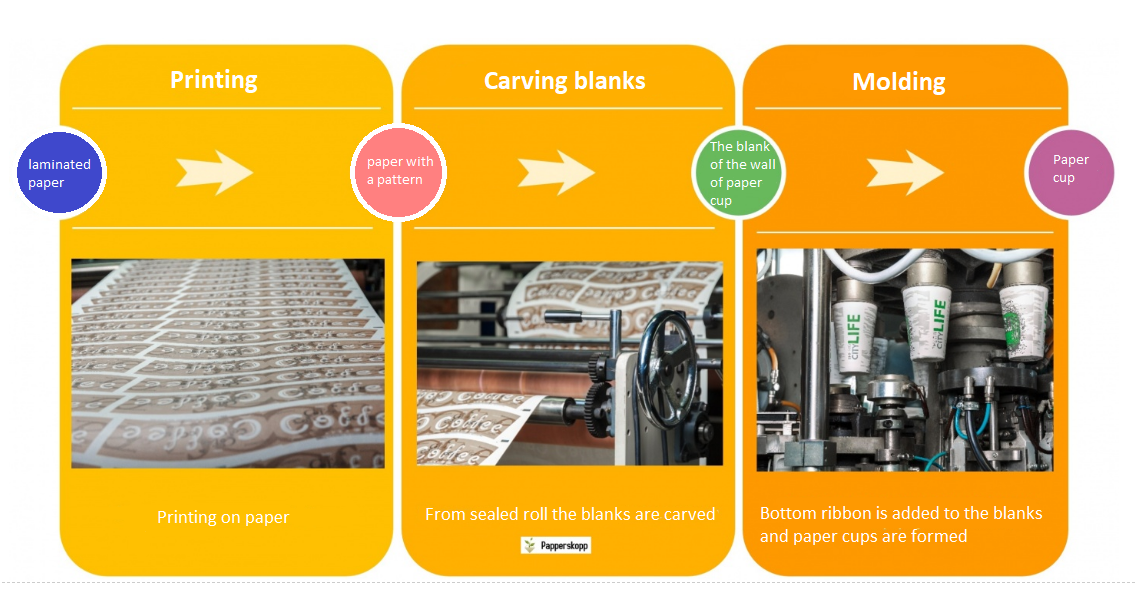

The first stage of paper cup production is printing on paper. For this purpose, flexographic, rotogravure or offset printing machines are used. At the output of this production stage, a roll of paper with a pattern is obtained.

The second stage of production is carving blanks. A roll of paper with a printed pattern is placed on the die-cutting machine, and in the output there are: the blanks, the future walls of the paper cups, and the burrs, the pieces of paper that are subsequently recycled.

The third and final stage of production is the molding of paper cups. The machine that performs this operation is called ‘cup making’ machine. At first, the blank of the wall of the paper cup is twisted into a cone and the side seam is sealed. This is done by melting a plastic layer of paper under the influence of ultrasound or heat. Then a bottom is cut from the paper tape, it is inserted into the cone of the walls of the cup, after which the bottom of the cup is sealed. This operation also occurs by means of the melting of polyethylene paper standing.

The last stage of molding the cup is the rolling of the neck of the cup.

Thus, glue is not used in the manufacture of paper cups.